Producing durable backlit matte flex banners requires careful consideration of several critical manufacturing factors to ensure they meet the rigorous demands of outdoor environments. These banners are pivotal in modern outdoor advertising due to their ability to combine the benefits of backlighting with a non-glossy, matte surface that minimizes glare and enhances visibility.

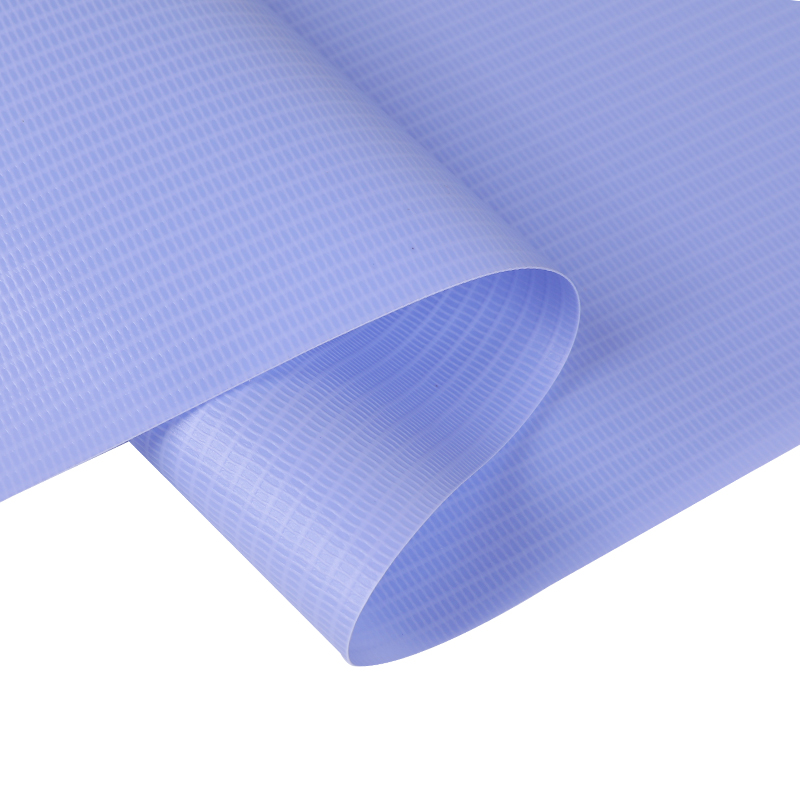

Firstly, the choice of materials plays a fundamental role in determining the banner's durability and performance. Typically made from PVC (polyvinyl chloride) or similar synthetic materials, backlit matte flex banners are selected for their flexibility, weather resistance, and UV stability. The thickness of the material is significant, with thicker variants offering enhanced resistance against tearing and stretching, which is crucial for withstanding the stresses of outdoor installation and exposure to wind.

Manufacturers employ specialized coatings and treatments to achieve the matte finish of these banners. This matte surface is designed to diffuse light evenly, reducing reflections that could obscure visibility and readability of the printed content. These coatings must be durable to withstand outdoor conditions without deteriorating over time, ensuring the banner maintains its aesthetic appeal and functional clarity throughout its lifespan.

Printing technology also plays a vital role in the manufacturing process of backlit matte flex banners. High-quality printing techniques using UV-resistant inks are employed to ensure vivid colors and sharp details that remain vibrant when the banner is backlit. This not only enhances the visual impact of the advertising message but also contributes to the banner's longevity by resisting fading from prolonged exposure to sunlight.

Weather resistance is a critical consideration. Outdoor banners are exposed to harsh elements such as sunlight, rain, and temperature fluctuations. The material used in backlit matte flex banners is treated to resist UV degradation and water ingress, preventing premature deterioration. Additionally, reinforcements such as hemming, stitching, or heat welding are often employed to strengthen the edges and corners of the banner, ensuring it remains intact and secure during installation and throughout its display period.

Advantages of backlit matte flex banners include their ability to remain visible and attractive in various lighting conditions, particularly low-light environments where the backlighting ensures continuous visibility. The matte finish reduces glare, making the banners suitable for areas where direct sunlight or artificial lighting could otherwise obscure the message. This makes them highly effective for outdoor advertising campaigns, large-scale signage, and promotional displays where visibility and durability are paramount.

Manufacturing durable backlit matte flex banners involves a comprehensive approach that encompasses material selection, coating technologies, printing methods, and weather-resistant treatments. By addressing these key considerations with precision and expertise, manufacturers can produce banners that not only meet but exceed the expectations for outdoor durability and visual impact, ensuring they remain a preferred choice for effective and long-lasting outdoor advertising solutions.