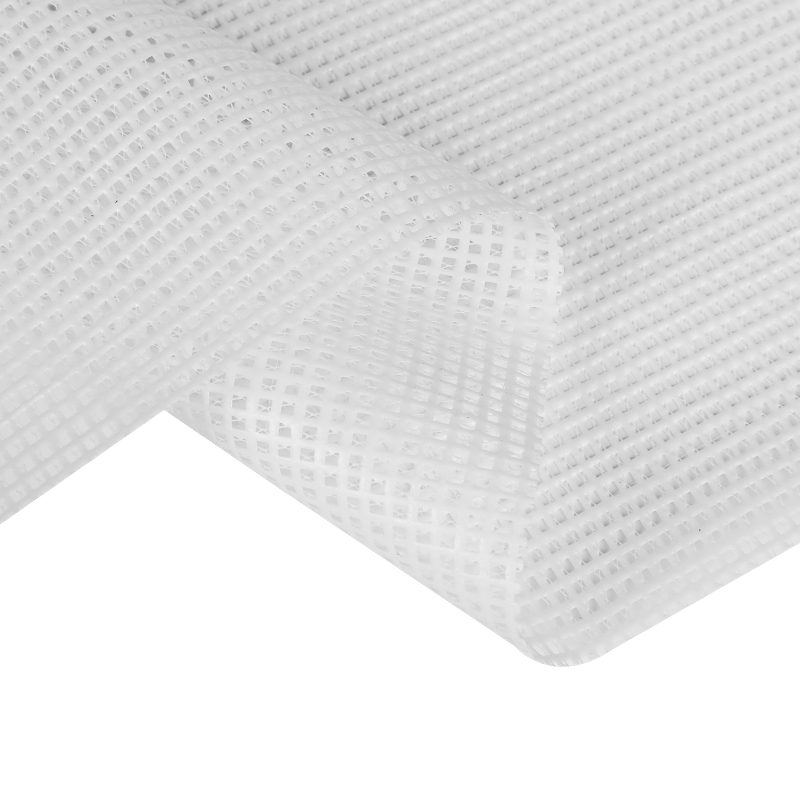

Preparing inkjet mesh cloth properly before printing is crucial to achieving optimal results and ensuring that the final print meets high standards of quality. Inkjet mesh cloth, distinguished by its grid-like structure, offers unique advantages for printing, such as enhanced ink absorption and vibrant color reproduction. However, these benefits can only be fully realized with appropriate preparation and treatment.

Start by thoroughly cleaning the surface of the inkjet mesh cloth to remove any dust, dirt, or contaminants that could interfere with the printing process. Use a soft, lint-free cloth or an air blower to ensure the cloth is free from particles. This step is fundamental as any debris on the surface can lead to uneven ink application and compromised print quality. Once the cloth is clean, you may need to apply a pre-treatment solution depending on the type of ink and cloth used. Pre-treatments are designed to improve ink adhesion and enhance color vibrancy. Follow the manufacturer's instructions carefully, applying the solution evenly and allowing the cloth to dry completely before proceeding with printing.

Compatibility between the ink and the inkjet mesh cloth is another critical factor. Different cloths are designed to work with specific types of inks, such as dye-based or pigment-based inks. Ensure that the ink you plan to use is suitable for the cloth to avoid issues with ink adhesion and color accuracy. Adjust your printer settings accordingly, taking into account the type of cloth and ink to optimize the print quality. This may involve setting adjustments for paper type, print quality, and ink density.

Before committing to a large print job, conduct a test print on a small section of the cloth or on a sample piece. This test will help you assess color accuracy, ink absorption, and overall print quality, allowing you to make any necessary adjustments before the final print. Handling the cloth with clean gloves or ensuring your hands are free from oils and residues can prevent contamination that might affect the print.

Once printed, if you plan to stretch or frame the inkjet mesh cloth, ensure it is properly tensioned and aligned to avoid distortions or misalignments. Proper stretching and framing techniques are essential to maintain the integrity of the print and ensure a professional finish.

Inkjet mesh cloth is celebrated for its ability to produce high-resolution, vibrant prints with excellent color reproduction, making it a preferred choice for artists and commercial printers alike. By following these preparation and treatment guidelines, you can harness the full potential of inkjet mesh cloth, resulting in prints that are not only visually stunning but also durable and long-lasting.