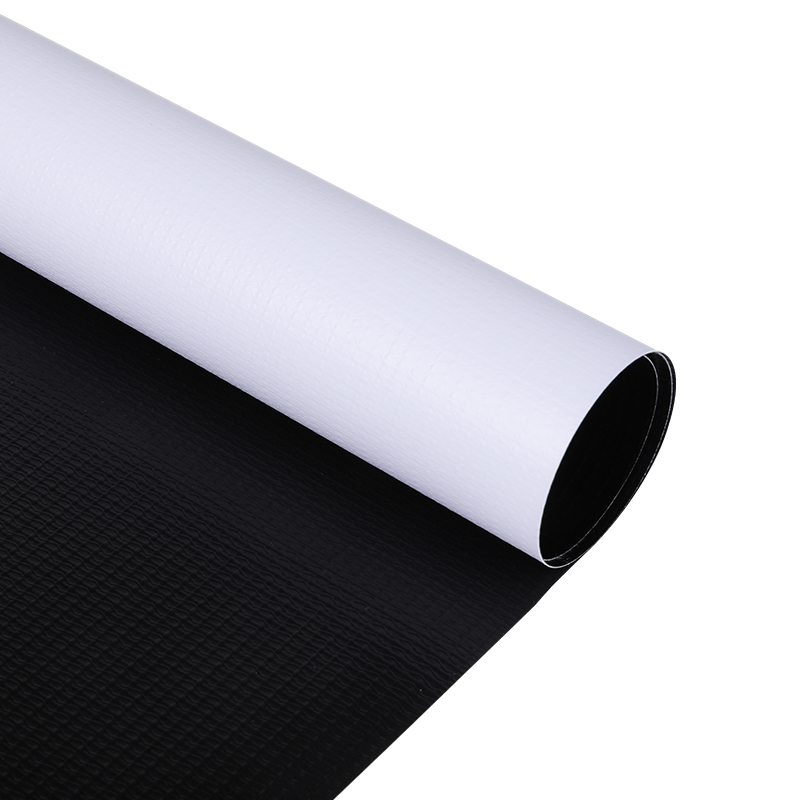

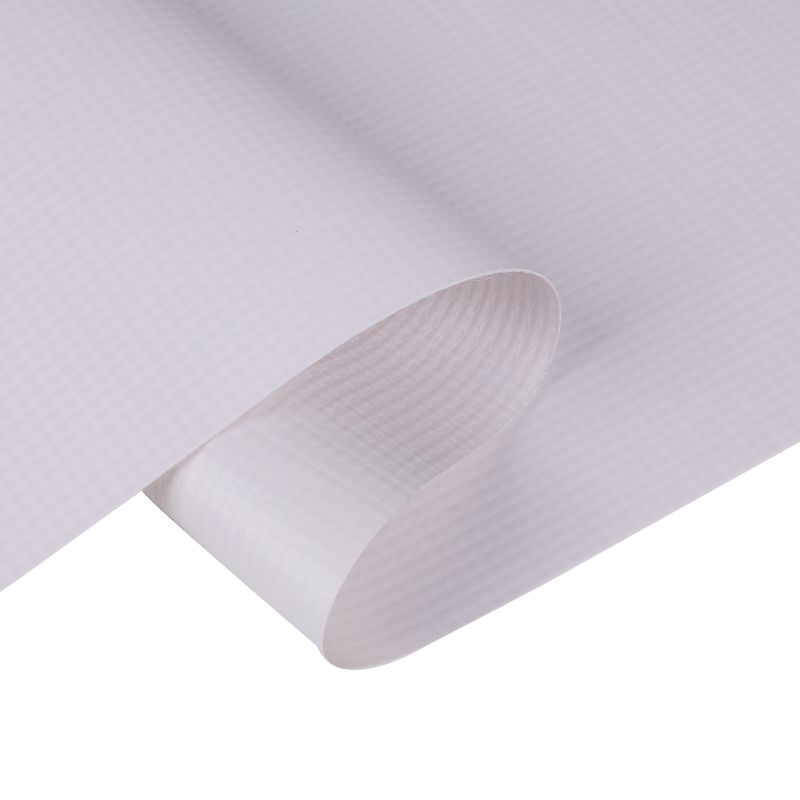

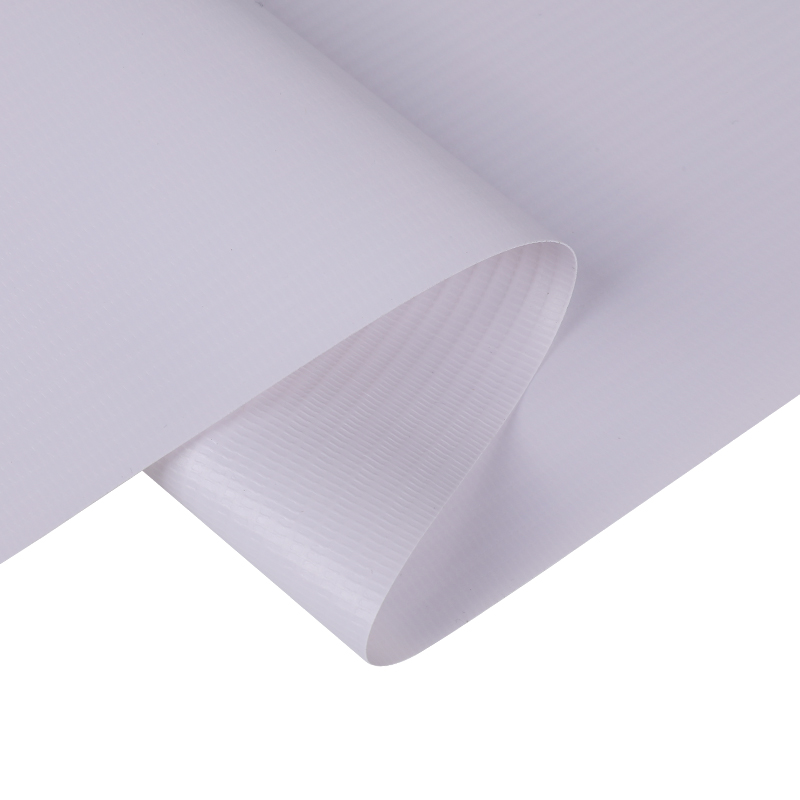

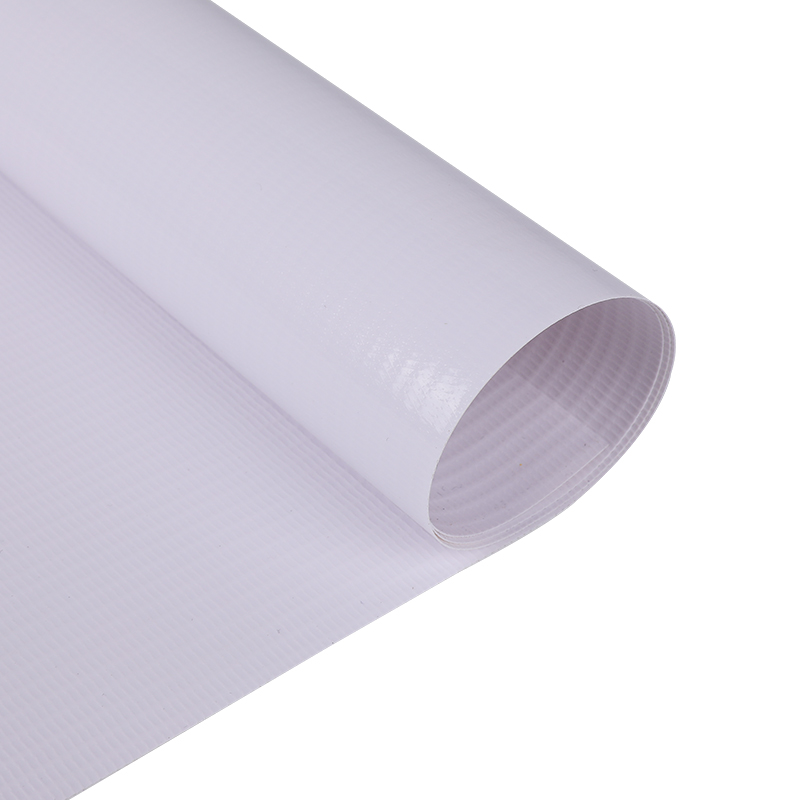

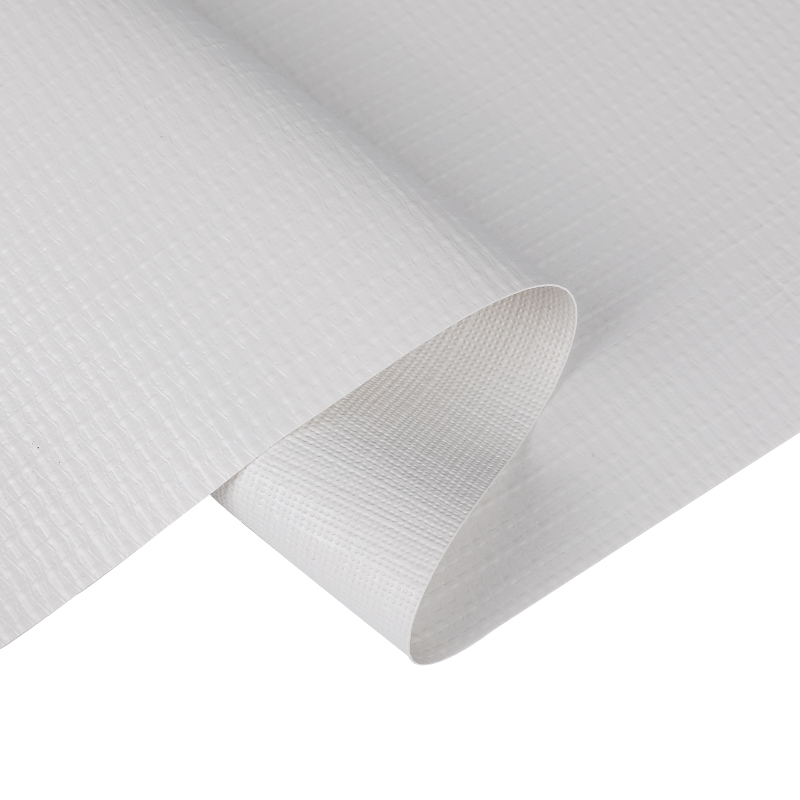

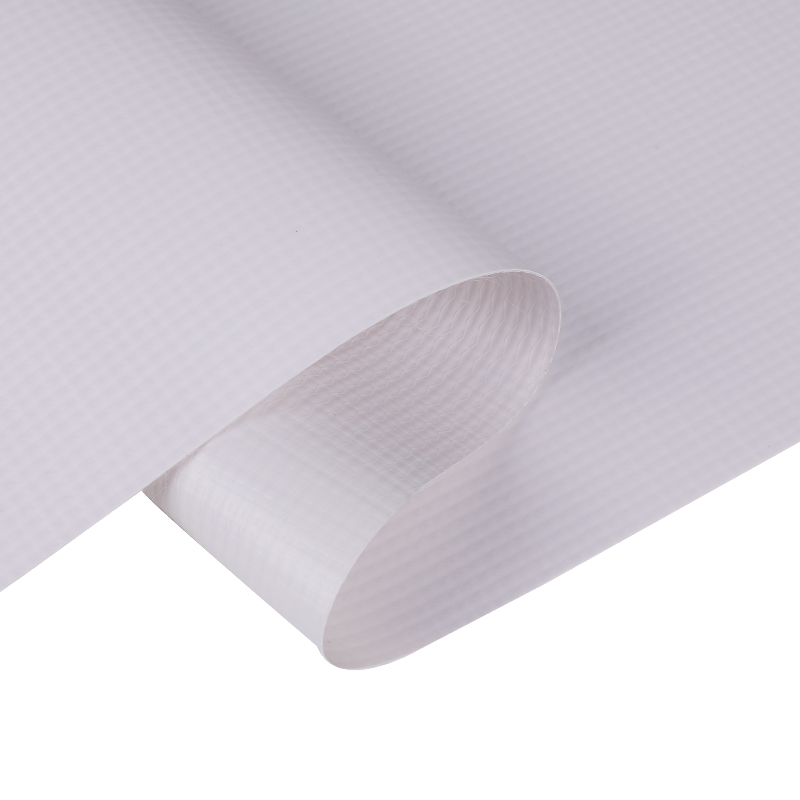

Coated tarpaulins are renowned for their durability and versatility, making them a popular choice for various applications, from industrial uses to outdoor events. However, even the most robust tarpaulins can suffer from wear and tear, requiring repair to extend their lifespan and maintain functionality. Understanding the most common methods for repairing coated tarpaulins and their effectiveness is crucial for ensuring the material's continued performance.

One of the most straightforward and commonly used repair methods is patching with adhesive patches. This technique involves applying a pre-cut patch of coated tarpaulin or a similar material over the damaged area, secured with a strong adhesive. The effectiveness of this method largely depends on the quality of the adhesive and the thoroughness of the application. For best results, the damaged area should be clean and dry before applying the patch. This method is effective for small to medium-sized tears and holes, providing a quick and durable fix that restores the tarpaulin's water resistance and overall integrity.

Another effective repair method is using specialized tarpaulin repair kits, which often include adhesive compounds and sealants designed specifically for coated materials. These kits usually contain a combination of liquid adhesives and fabric patches, which work together to repair tears and punctures. The adhesive is applied to the damaged area, and the fabric patch is placed over it. Once the adhesive cures, it forms a strong bond that can withstand environmental stresses. This method is highly effective for both small and large repairs, offering a robust solution that maintains the tarpaulin's protective qualities.

For more extensive damage, such as large tears or severe punctures, sewing the damaged area may be necessary. This involves using a heavy-duty sewing machine and a strong, UV-resistant thread to stitch the torn sections together. This method can be highly effective in providing a permanent repair, but it requires skill and proper equipment to ensure that the stitches are tight and durable. Additionally, sewing may be used in combination with adhesive patches for added reinforcement, particularly in high-stress areas.

In some cases, a combination of these methods may be the best approach. For instance, a large tear might first be sewn to secure the edges and then covered with an adhesive patch to seal the repair and restore the tarpaulin's waterproofing. This multi-step approach ensures that the tarpaulin is not only structurally reinforced but also protected from moisture and further damage.

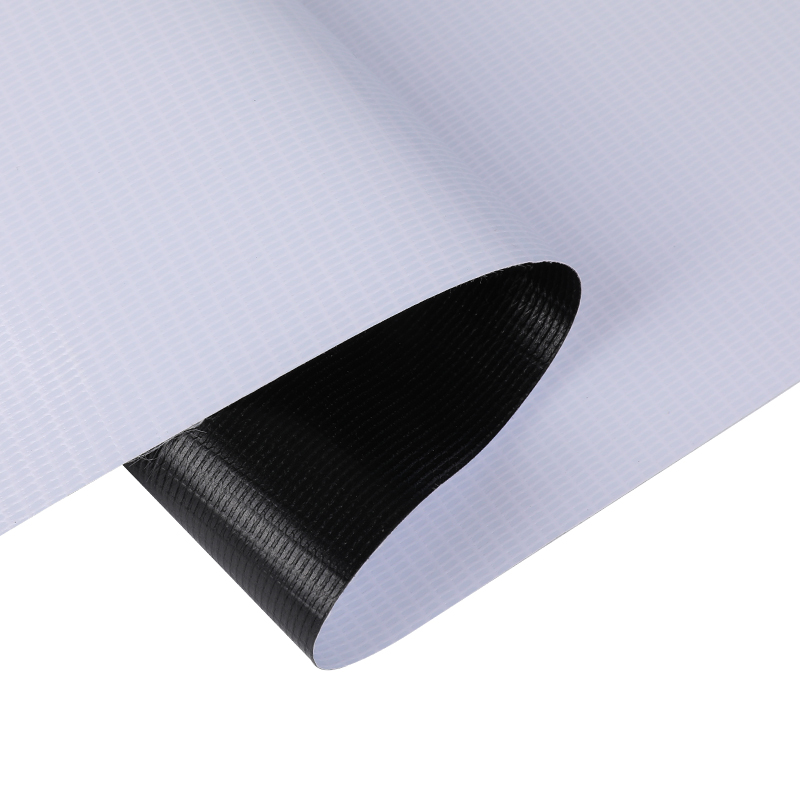

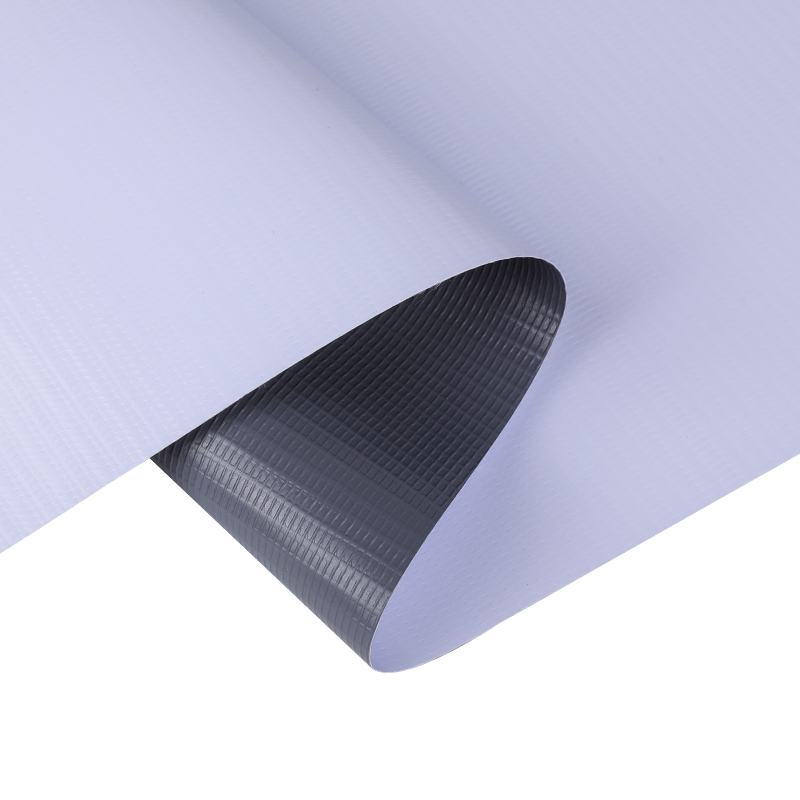

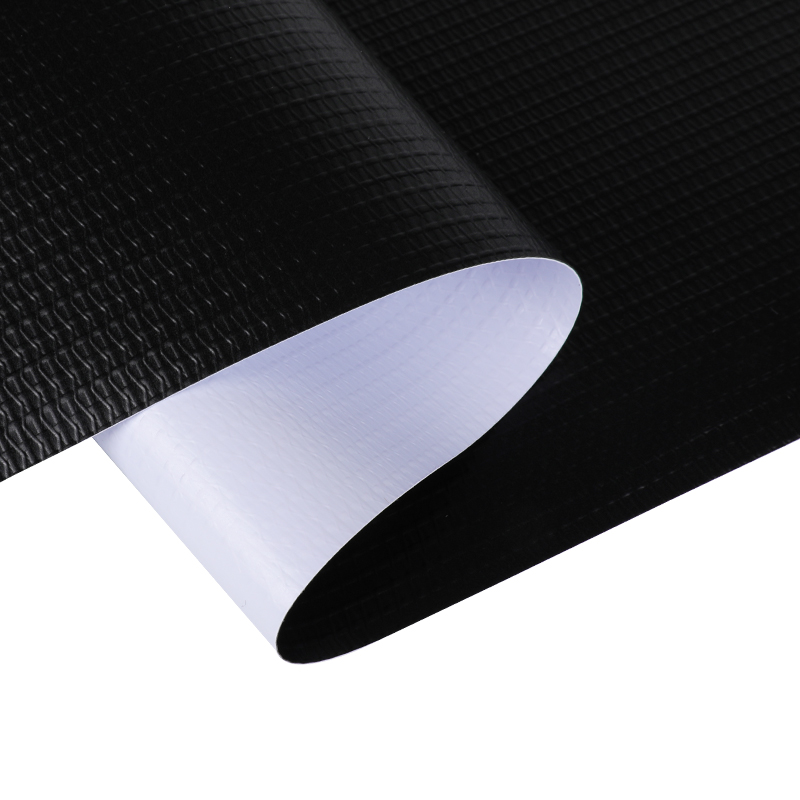

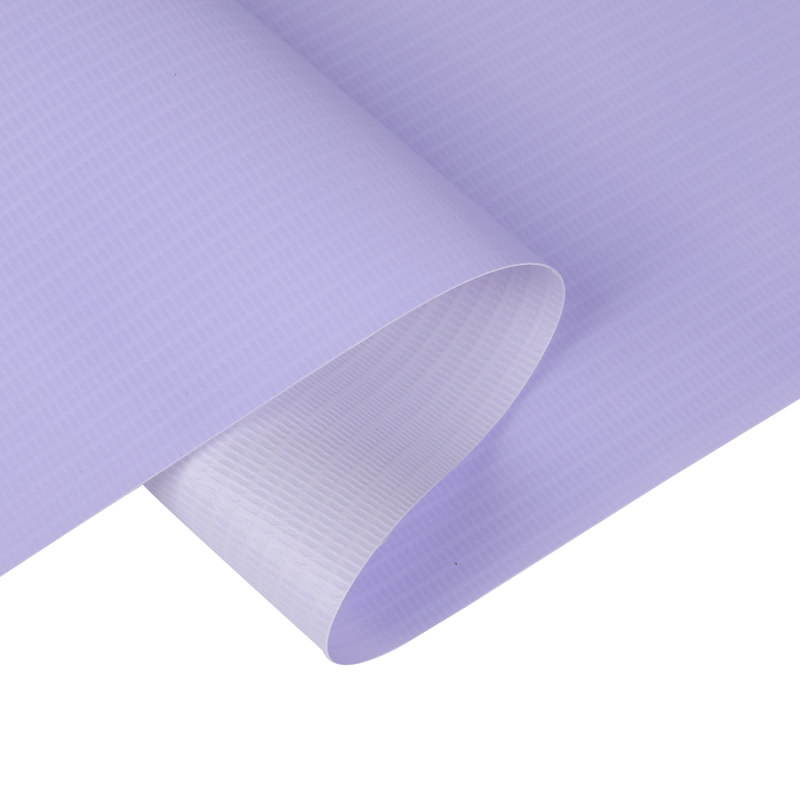

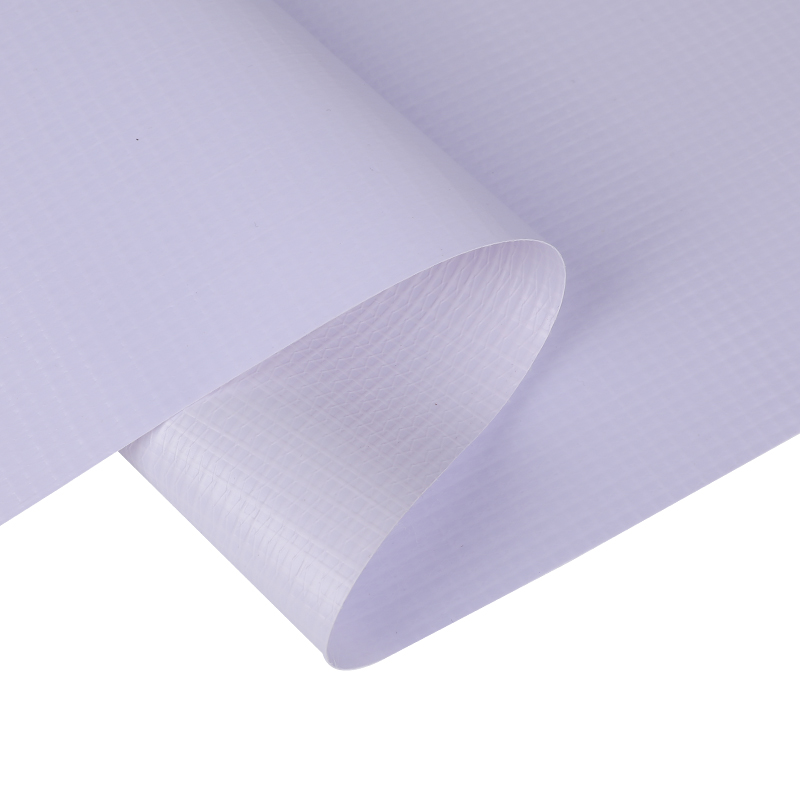

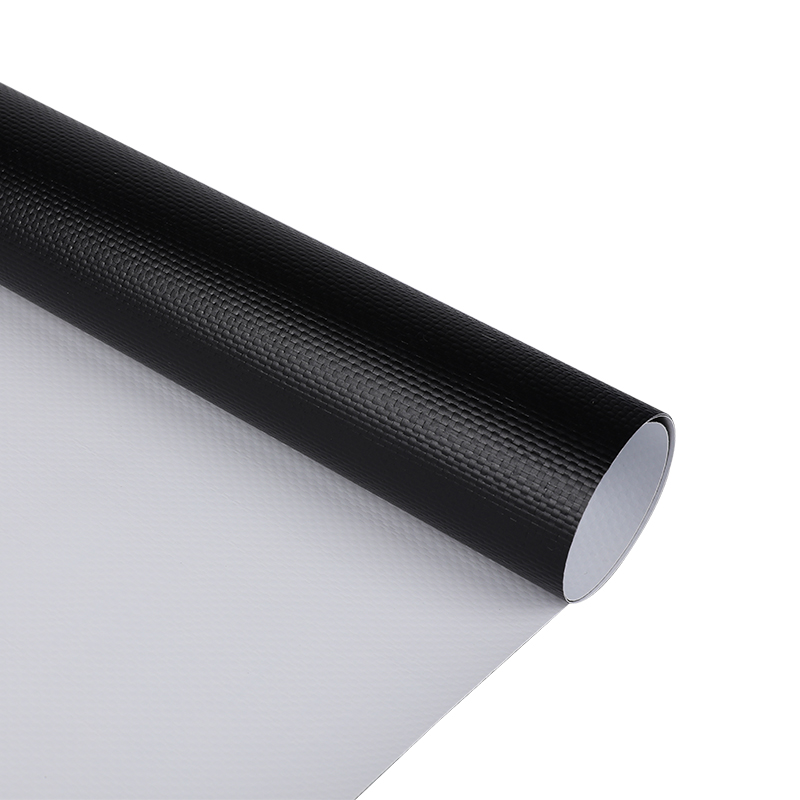

Our Coated tarpaulins products, known for their superior durability and resistance to elements, are designed to handle a variety of tough conditions, making them an excellent choice for applications that require reliable performance. By employing effective repair methods, such as adhesive patching, specialized repair kits, and sewing, users can significantly extend the life of their tarpaulins, ensuring continued protection and functionality. Proper maintenance and timely repairs are key to maximizing the benefits of coated tarpaulins, allowing them to continue performing at their best even after sustaining damage.

Repairing coated tarpaulins effectively involves selecting the right method based on the type and extent of the damage. Whether through adhesive patches, repair kits, sewing, or a combination of these techniques, timely and proper repair ensures that coated tarpaulins remain a valuable and functional asset in various applications.