Frontlit flex banners are designed to be structurally strong and durable, specifically engineered to withstand outdoor conditions and resist tearing or disintegration. However, their strength and longevity can vary depending on factors such as the quality of the material, the thickness of the banner, and the environmental conditions to which they are exposed. Here are some considerations regarding the structural strength of frontlit flex banners:

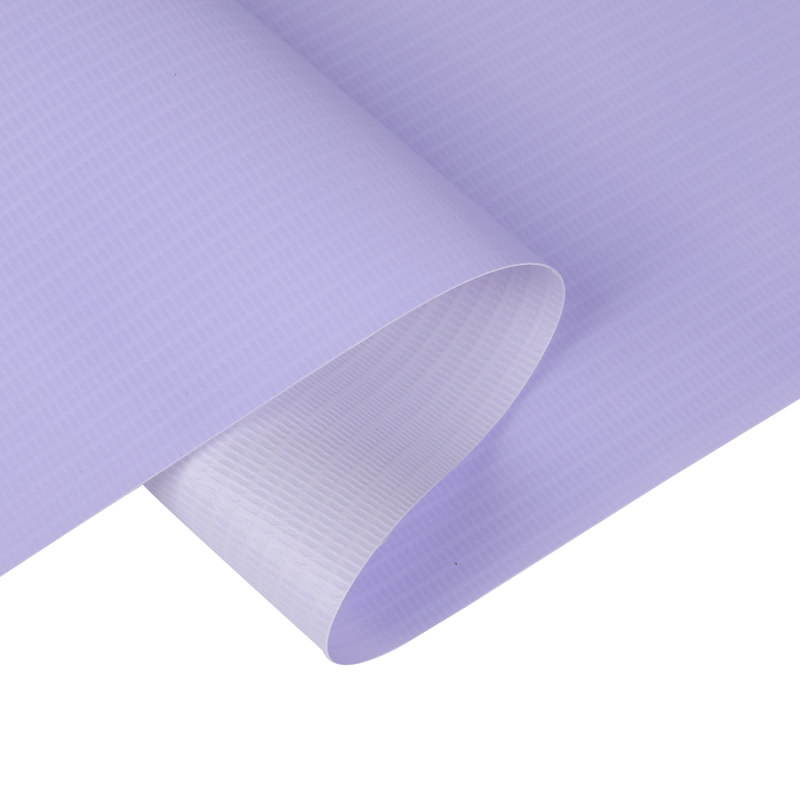

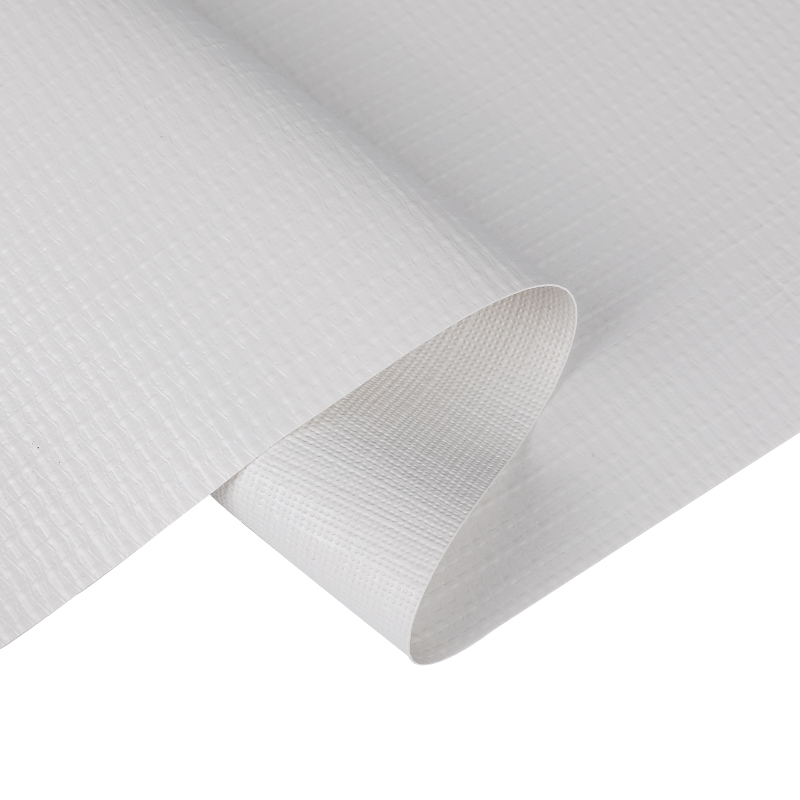

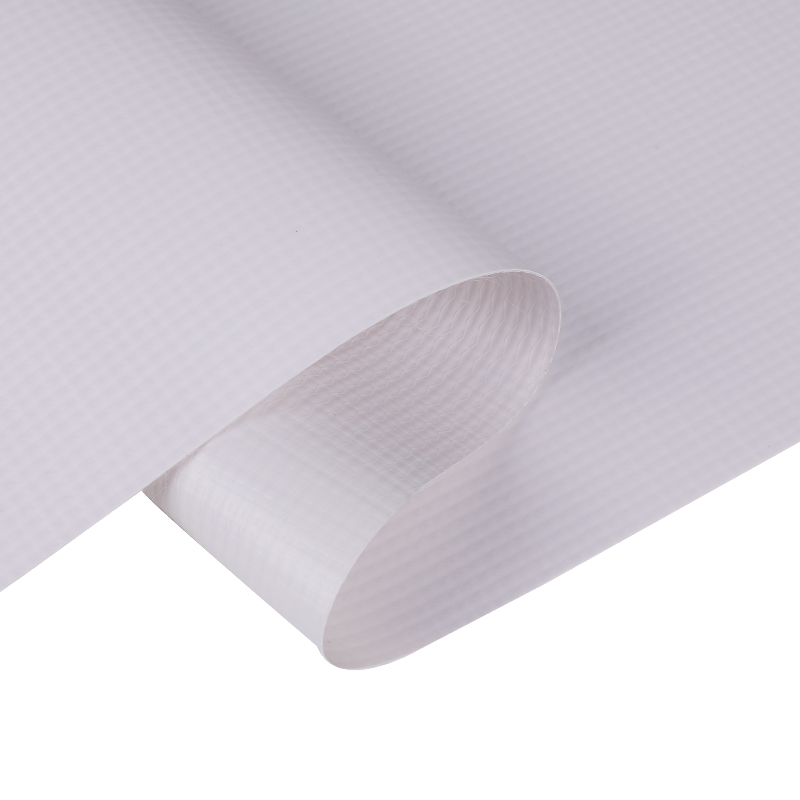

Material Quality: The quality of the PVC material used in the banner significantly influences its strength and durability. High-quality frontlit flex banners are made from robust and tear-resistant PVC that can withstand the stresses of outdoor exposure.

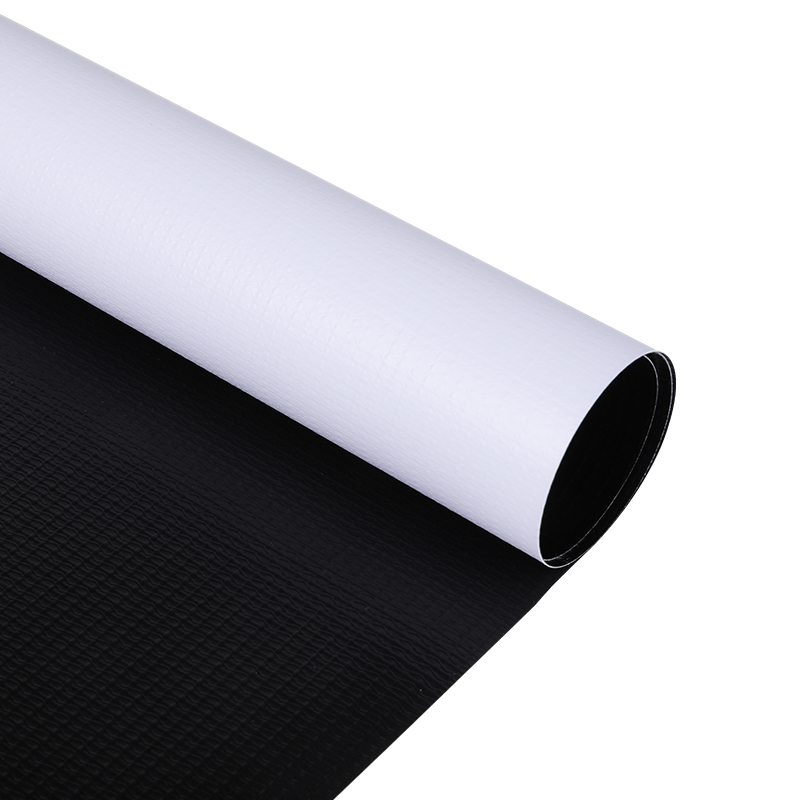

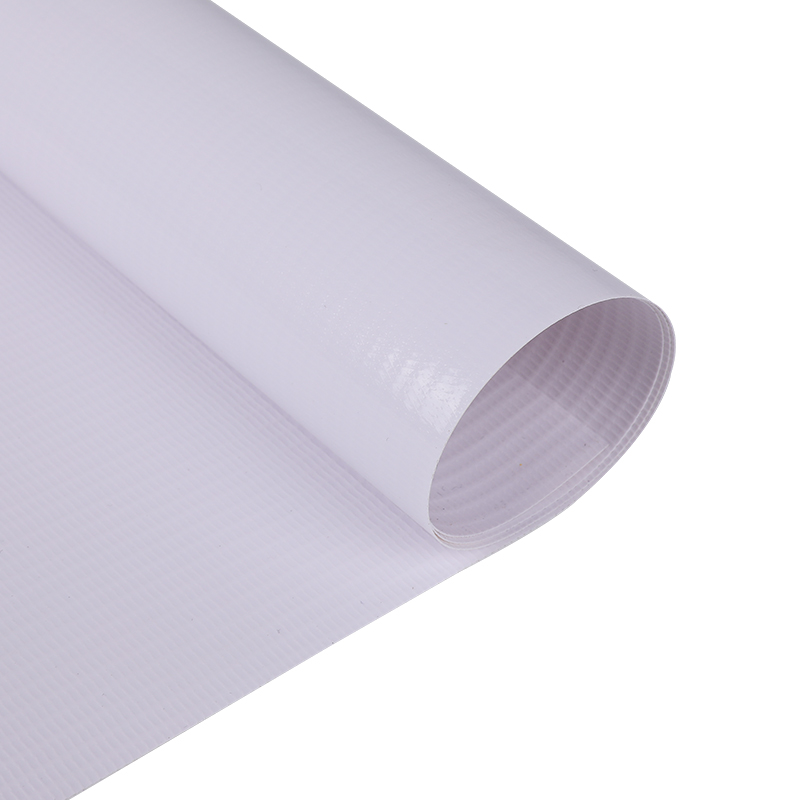

Thickness: Frontlit flex banners are available in various thicknesses, typically measured in millimeters or microns. Thicker banners tend to be stronger and less prone to tearing than thinner ones. The choice of banner thickness often depends on the intended application and expected environmental conditions.

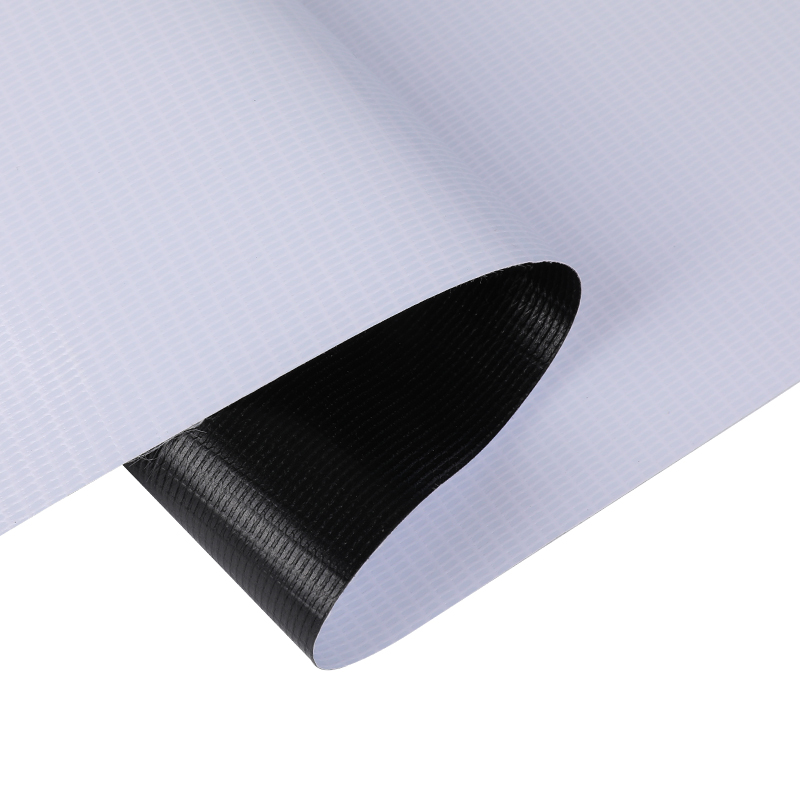

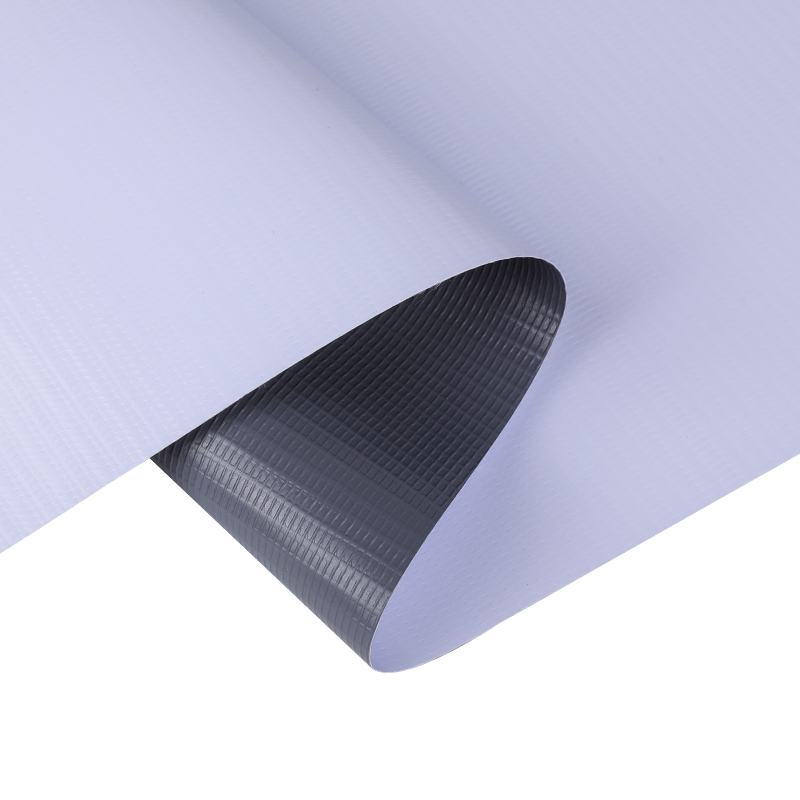

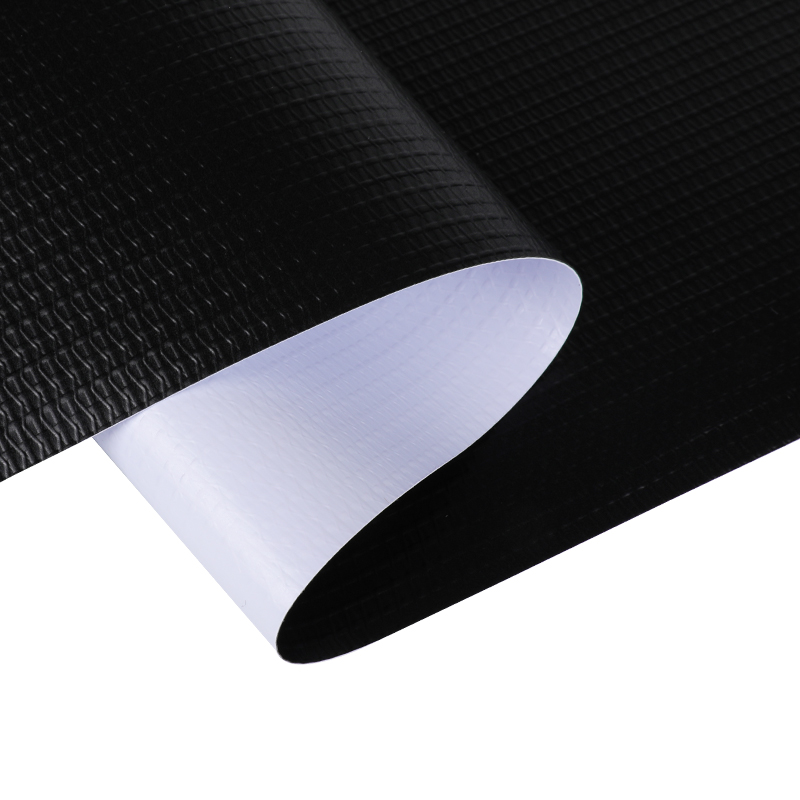

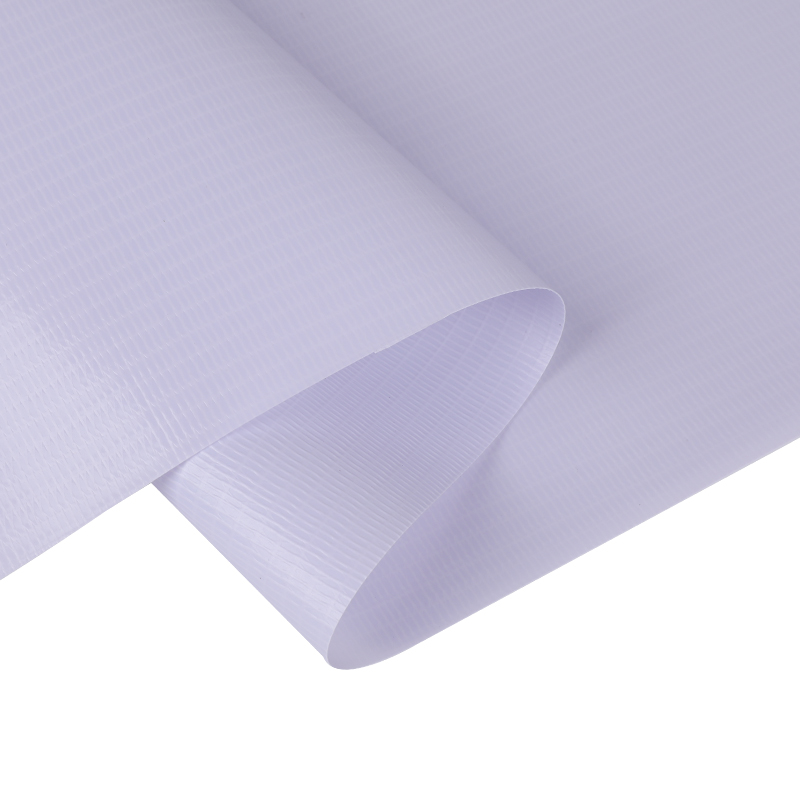

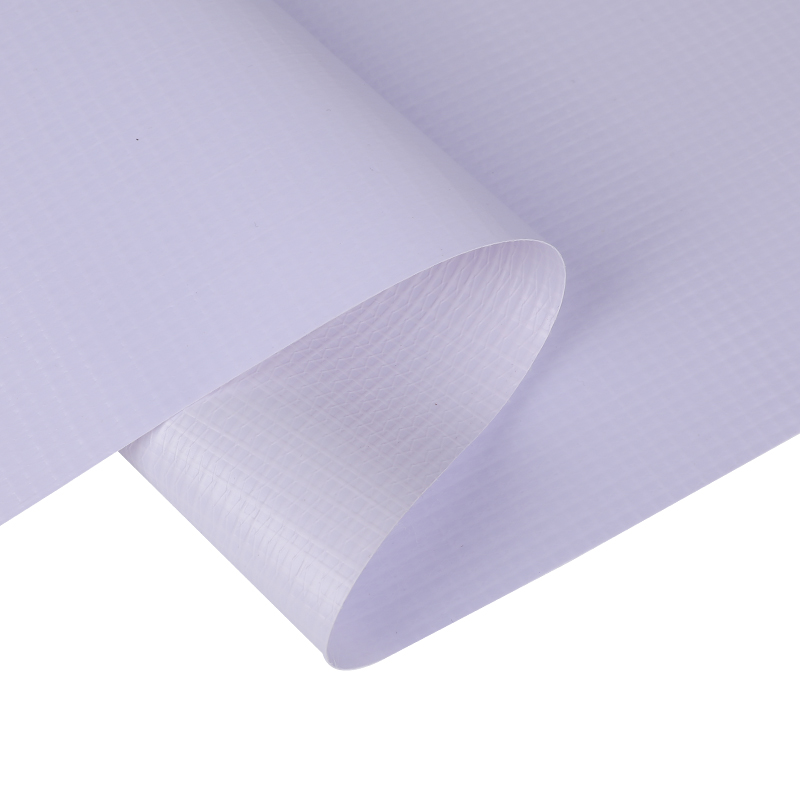

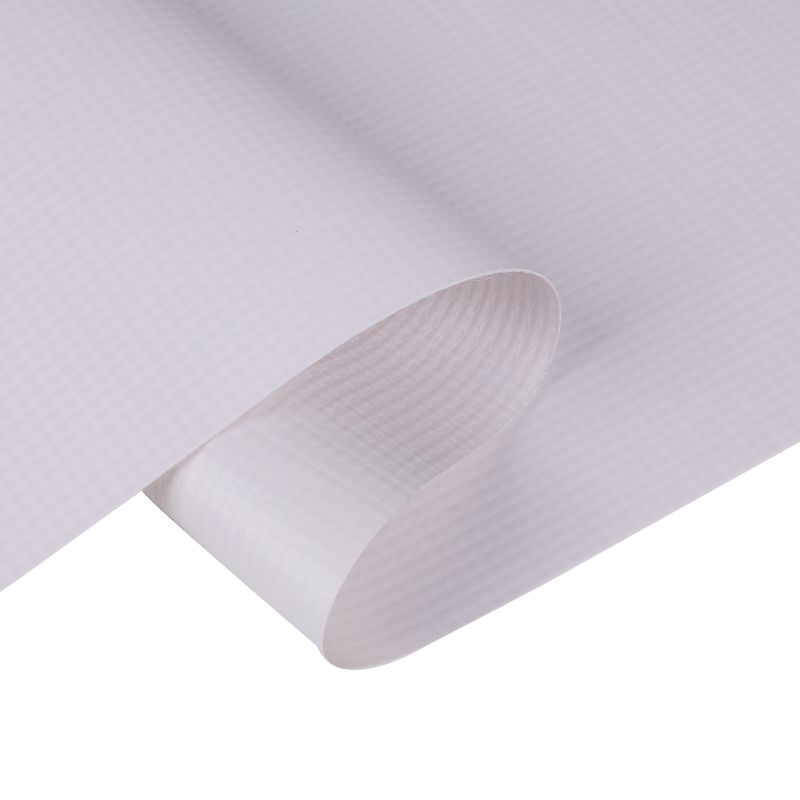

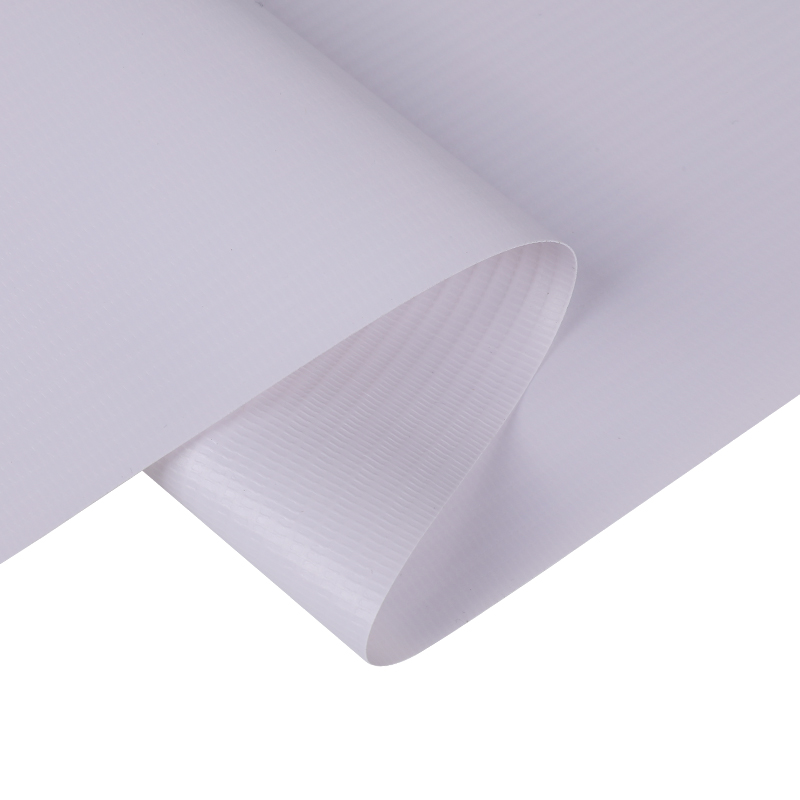

Reinforcements: Some frontlit flex banners may include additional reinforcements or layers to enhance their structural integrity. These reinforcements may include polyester or other materials that add strength and tear resistance.

UV Resistance: UV-resistant coatings and treatments are often applied to frontlit flex banners to protect them from the damaging effects of sunlight. UV exposure can weaken the material over time, so UV resistance is crucial for outdoor durability.

Lamination: Lamination, which involves applying a protective film or layer over the banner's surface, can further enhance its strength and resistance to tearing, as well as protect the printed graphics.

Weather Resistance: Frontlit flex banners are engineered to withstand various weather conditions, including rain, wind, and temperature fluctuations. Their resistance to environmental factors contributes to their durability.

Proper Installation: Correct installation methods, including proper tensioning and secure fastening, can help prevent banners from tearing or disintegrating due to wind or other forces.

Maintenance: Regular maintenance, such as cleaning and inspecting for any signs of wear or damage, can extend the lifespan of frontlit flex banners. Prompt repairs can prevent minor issues from becoming major problems.