In the world of printing, achieving high-quality results is paramount, whether for personal projects, business endeavors, or creative pursuits. As technology advances, new printing methods emerge, each offering unique advantages and considerations. One such innovation is Inkjet Mesh Without Liner, a versatile substrate that has garnered attention for its potential to revolutionize printing processes.

Understanding Inkjet Mesh Without Liner

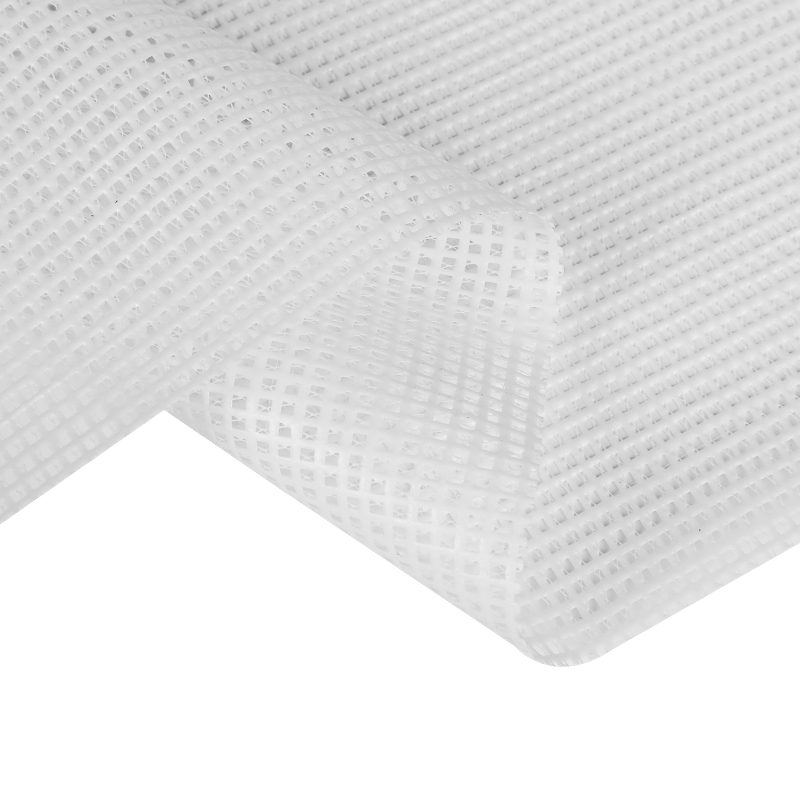

Before delving into the comparison, let's first understand what sets Inkjet Mesh Without Liner apart. Unlike traditional printing substrates like paper or fabric, Inkjet Mesh Without Liner features a mesh structure, typically made from materials like polyester or nylon. This mesh provides structural support while allowing ink to pass through, resulting in prints with unique textures and characteristics.

Comparing to Traditional Methods

Inkjet Printing on Paper:

Inkjet printing on paper is a tried-and-true method known for its versatility and ease of use. However, compared to Inkjet Mesh Without Liner, paper lacks the durability and texture that the mesh substrate provides. While both methods can achieve similar levels of detail and color accuracy, Inkjet Mesh Without Liner offers a distinct tactile experience that may be desirable for certain applications.

Screen Printing:

Screen printing is renowned for its vibrant colors and longevity, particularly on textiles and uneven surfaces. While Inkjet Mesh Without Liner can rival screen printing in terms of color vibrancy and durability, it may not achieve the same level of opacity due to the thinner ink layers. However, the versatility of Inkjet Mesh Without Liner allows for printing on a wider range of materials and surfaces, offering unique creative possibilities.

Dye Sublimation Printing:

Dye sublimation printing excels in producing photo-realistic prints on fabrics and hard surfaces. While Inkjet Mesh Without Liner may not match the exact color vibrancy and detail of dye sublimation printing, it offers greater flexibility in terms of substrate compatibility and cost-effectiveness. Additionally, the texture of the mesh substrate adds a tactile dimension to prints that may appeal to certain audiences.

Laser Printing:

Laser printing is known for its crisp text and graphics on various substrates, including paper and cardstock. While Inkjet Mesh Without Liner may not achieve the same level of precision as laser printing, especially for fine lines and small text, it offers advantages such as the ability to print on non-flat surfaces and a wider range of compatible materials.